Ensuring employees are safe during work is paramount for businesses.

We sell several safety lockout accessories that assist in minimising the risk of unexpected accidents occurring in the workplace when working with electricity and other high risk situations.

In this post we discuss the different lockout options available.

What is a Lockout Device?

A lockout device uses a physical means such as a lock to hold an energy-isolation device in a safe position and prevent the energising of a machine or a piece of equipment.

The lockout device itself doesn’t de-energise equipment they are attached after the equipment has been isolated from the energy source.

Why Do You Need to Lockout Devices?

To lockout means to physically neutralise all energy sources in machinery or equipment, most commonly by applying locks, before beginning any maintenance or work.

The primary purpose of lockout is to prevent all energy isolation devices (switch, circuit breaker or valve) from accidentally or inadvertently being operated while workers are working on equipment.

Electrical Power Lead Lockout Device

Electricity is one of the most dangerous things workers can deal with as part of their job.

If the electrical current isn’t turned off or disconnected before work commences there is a high chance of electrocution which can lead to serious injury or even death.

Our electrical power lead lockout device is the ideal safety accessory for mitigating some of the risk of electrocution when workers are working around electricity.

The device surrounds an electrical plug and is padlocked closed to prevent accidental re-connection or turning on of electrical current whilst work is being carried out.

The device features double padlock holes for extra redundancy so it can be locked by up to two employee padlocks when a group of employees are working.

The lockout device can only be removed when the last employee from the group removes their padlock.

It also features high visibility ‘Danger Do Not Operate’ warnings to alert workers who come across the locked-out device not to operate.

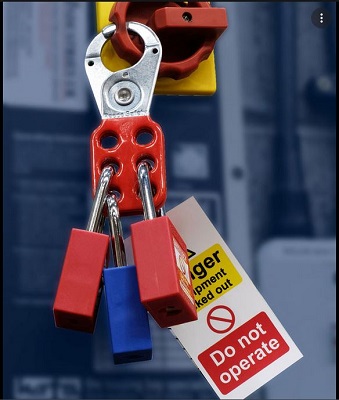

Safety Lockout Hasps

Our lockout hasps are manufactured using high quality aluminium and are powder coated.

They are the ideal lockout solution for isolating a single energy source such as a piece of machinery or a power switch.

The design allows up to six employees to lockout the energy source with their own padlock for extra redundancy when groups of workers are working on the same source.

The lockout hasp can only be unlocked and removed when the last employees’ padlock is removed ensuring the energy source isn’t accidentally turned on when some employees continue to work whilst others have finished.

4mm Steel Cable Lockout Device

Our steel cable is a multi-function cable lockout device that is ideal for locking out gate valves, multiple electrical points, steering wheels, or applications where scissor hasp won’t fit.

With a length of 1.8m the cable can be weaved into and/or around a device then pulled tight and locked via a single or multiple padlocks.

It also features high visibility Danger Do Not Operate warnings to alert workers who come across the locked-out device not to operate.

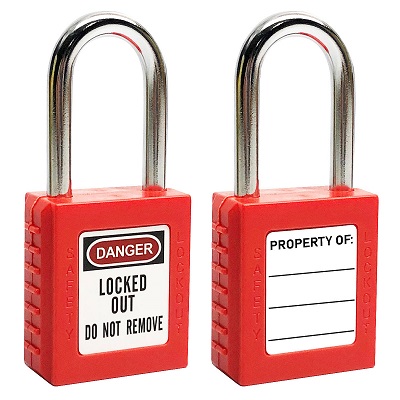

Safety Lockout Isolation Padlocks

Our safety lockout isolation padlocks have a shackle height of 38mm and a shackle diameter of 6.5mm, they’re compatible with all three of the lockout devices described above.

The locks comply with Australian standards for extra redundancy as the key is retainedin the lock while unlocked to prevent the key being removed while unlocked, this ensures the padlock is never incorrectly left unlocked.

The back of each padlock has an area for the optional writing of the owners’ details which is especially helpful for team situations, so each padlocks owner is clearly identifiable indicating they are still working.

Lockout devices and padlocks are some of the many safety accessories we sell.

View our full range of safety accessories and PPE.

Need help deciding which safety lockout device is best for your application?

Contact our online part team via our enquiry form and they will specify the correct device.