Before the commencement of each shift operators should always conduct a pre-start inspection of the forklift they are going to operate.

As outlined in our previous post the inspections require operators to complete visual, physical and operational checks of the unit to ensure it is in safe working order.

If any major issues are detected during the pre-start inspection it is imperative that the unit is removed from operation until they’re rectified and the unit is safe for operation.

As part of OH&S procedures forklifts that are unsafe to operate must be tagged out and have a safety tag attached to them to notify operators they’re not to be used until repairs have been completed.

Adaptalift Group sells a variety of forklift safety tags through our online store that can be used to tag units out of service.

Tags available include:

- ‘Out of Service’ Machinery Lockout Tags

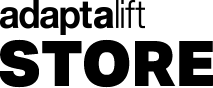

- Commissioning in Progress Tags

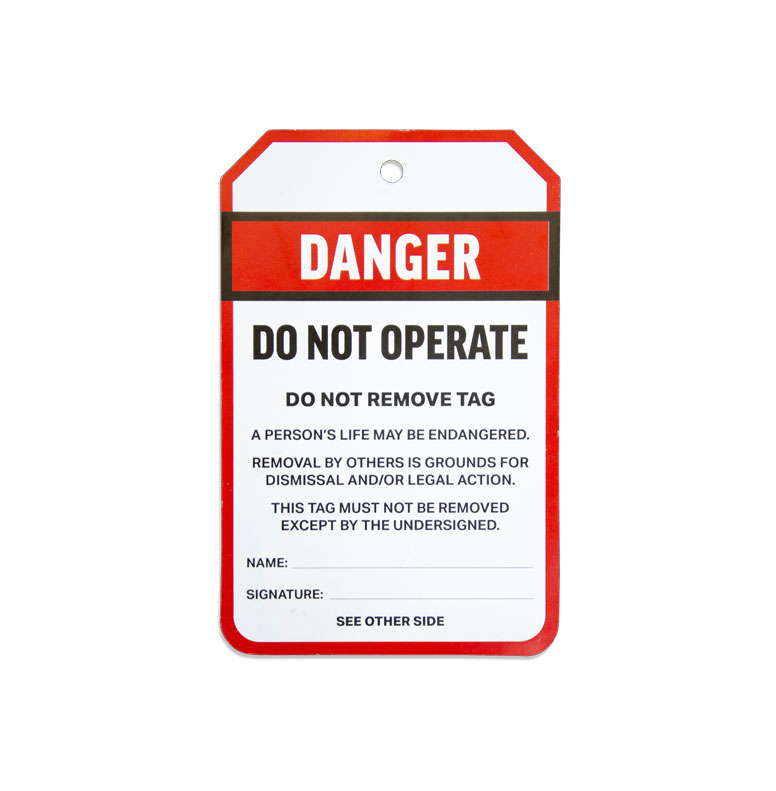

- Danger Do Not Operate Tags

All tags measure 90mm x 140mm in size and are made with 250gsm thick card to prevent damages from moderate handling.

Both sides of the tags can be written on to record important information, whilst a pre-cut hole at the top of the tags allows for the easy attachment to machinery via string or zip tie.

‘Out of Service’ Machinery Lockout Tags

Out of service machinery lockout tags can be easily attached to forklifts where maintenance or repairs must be completed following a pre-start inspection.

The tag allows important information regarding problems to be accurately recorded including:

- Date

- Time

- Job Description

- Responsible Employee

Once the tag has been attached to the forklift it must not be removed until all maintenance and repairs have been completed and the unit is safe to operate again.

Commissioning In Progress Tags

When new equipment has been acquired it is important that it is comprehensively inspected and tested for any problems that may have resulted from the manufacturing process or during transport.

To notify employees that a unit is in the process of being inspected before use a Commissioning in Progress tag can be temporarily attached to the unit, so operators don’t try to operate the unit prematurely.

Once all necessary inspections and maintenance has been completed successfully the tag maybe removed and the forklift enter into active operation.

Danger Do Not Operate Tags

Forklifts and machinery that is fitted with a Danger Do Not Operate Tag have been deemed faulty or broken and have been removed from service.

The units must not be operated under any circumstances due to potential hazards that may endanger an operator’s life.

Similar to the tags above these tags allow the date, time and details of faults to be documented for quick reference.

In addition the front side also features space for a technician or person responsible for repairs to sign their name and signature assigning them responsibility over the unit.

These tags must not be removed by anyone else other than the worker who has originally signed the tag when it was installed.

If someone other than signee removes the tag and operates the forklift without repairs being completed they’ve chosen to disregard OH&S protocols and operate an unsafe unit which may be grounds for dismissal and/or legal action against them depending on company policies.

For assistance with how to properly use forklift safety tags contact our team on 13 22 54 or fill-out a contact form and we will reply as soon as possible.