Conducting a pre-start inspection before the start of each shift is a process that will take a few important minutes that could prevent serious injury or death whilst ensuring that it is in optimal condition increasing its longevity.

Operators should undertake a pre-start check at the beginning of every shift or before they begin to operate a different forklift.

It is imperative operators never assume that a forklift has been left in a safe working order by the previous operator.

Proper pre-start inspections as defined by Safe Work Australia include both visual and physical safety checks that are listed below.

Visual Inspections

To complete a visual inspection operators must walk around the entire forklift looking for signs of damage or part degradation and report any problems to management or fleet managers for rectification.

Visual checks include:

- Check tyres for wear and tear

- Check lights and lenses for damage

- Check forklift gauges easily visible to the operator

- Check the forklift body and overhead guards for potential damage

- Check the forklifts mast, lift assembly and attachments are in good condition

- Check forklift tynes and backrest for cracks and fractures

- Check hydraulic hoses, couplings and cylinders for leaks or damage

- Check the forklift body under carriage for fuel or oil leaks

Physical checks include:

- Check LPG bottle for leaks

- Check battery connections aren’t corroded and connected correctly

- Check any attachments have been properly secured to the carriage

- Check the forklifts liquid levels including hydraulic fluid, brake fluid and coolant

- Check tyre pressure is correct

Once a comprehensive visual inspection has been completed with no issues discovered operators can safely start the forklift to conduct operational checks.

Operation Checks

Although a forklift may visually look in perfect condition, it is important operators also complete operational checks as it is better to find operational faults or problems before operations have commenced as it may be too late to avert any danger.

Operational checks defined by Safe Work Australia include:

- Checking the forklifts handbrake holds the unit in place to prevent it unnecessary rolling

- Check the transmission is working

- Check the brakes and inching pedal work to ensure the operator can stop the forklift during operations or in an emergency

- Check the forklift has full range of steering movement

- Check that the forklifts lift, tilt and side-shift controls work before they have a load positioned on the tynes and commence lifting operations

- Check that any warning devices such as lights, horns, indicators and reversing beepers or safety systems are operating correctly

- Check the dashboard gauges are working correctly

Forklift Inspection History

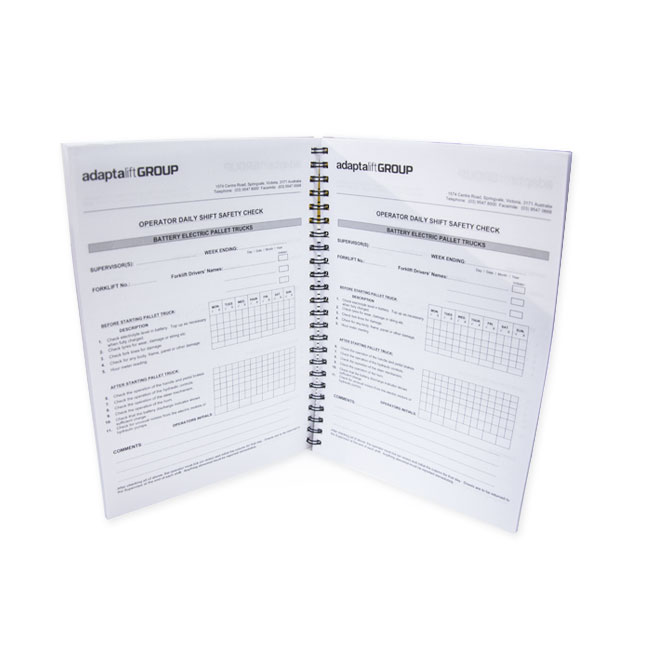

Similar to how we record evidence of having our cars serviced at regular intervals in the logbook, Adaptalift Group recommends the inspection history of all forklifts is recorded and kept with the unit for future reference.

This ensures that all problems operators detect are documented, so future operators can be made aware of issues or so fleet managers can take appropriate actions to have issues quickly rectified or the unit removed from operation for serious repairs.

Operators are able to document the results of their inspections using pre-start checklist books available for purchase.

The small A5 sized books are slim and easily fit into the document pockets of the majority of forklifts.

The checklist is quick and simple to use and guides operators through the series of visual, physical and operational checks to ensure the forklift is safe for operation.

In addition to pre-start checklist books Adaptalift Group offers posters and stickers that can be hung on walls or stuck to forklifts to remind operators to complete inspections before they commence work.

For further assistance with the implementation of forklift pre-start inspections contact our team on 13 22 54 or fill-out a contact form and we will respond as soon as possible.